Modern automated control systems

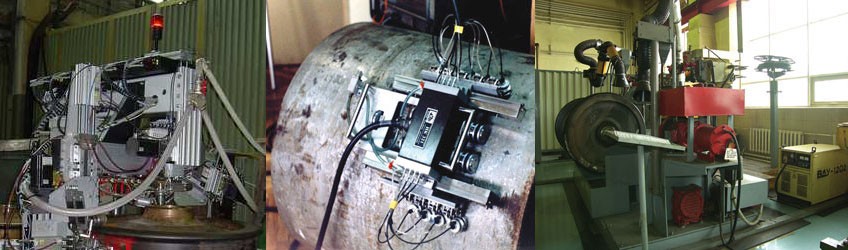

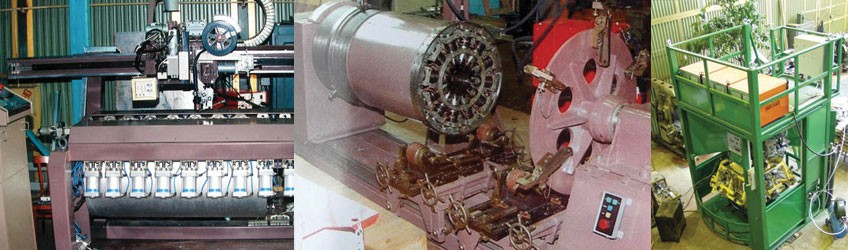

Modern automated control systems- are designed for welding equipment control. High level of control systems is achieved due to application of ingenious engineering solutions and advanced electronic components (programmable logic controllers, variable-frequency drives, sensor terminals, sensors and controls) from leading world manufacturers (Omron, Siemens, etc.). Technological process monitoring and control of equipment operation are performed by systems of visualization and parameter recording.

Control systems are developed, as a rule, by the order of large metallurgical plants for monitoring and control of production processes for any technological welding operations.

So, experts of the enterprise developedthe equipment of digital management - with position of the scanning electronic bunch and programming thermal investment

within the limits of zones heating provides discrete display of the electronic bunch - forMachine electronic beam spraying products in the vacuum chamber mounted by our enterprise in Seoul, Korea. The structure of a control system includes the programmed controller, a personal computer for registration of parameters process, the amplifier of capacity, the power supply and also a set of technological programs.

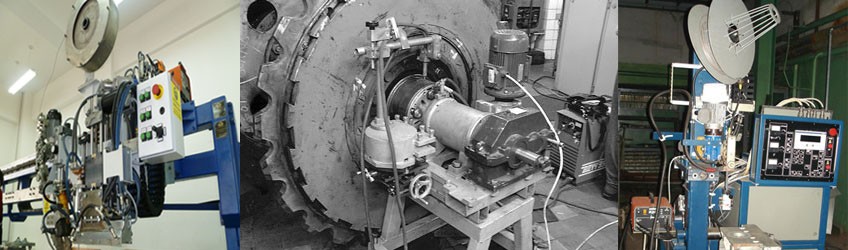

The last of our development -the equipment of management for Automatic machine of welding sheet bodies UD-682 which allows to carry out electroarc welding by a not fusing electrode. The developed control system is based on a method of automatic tracking position of a welding electrode on a voltage of the arch.

Our experts will make installation of cases and control panels, will carry out adjustment of electric equipment and also will train technicians of the Customer.