Above ground tanks. Design, inspection and repair

Our team has been working in the field of developing of the technology for the factory manufacture, erection and improvement of the construction cylindrical above ground tanks more than 65 years. Since 1994 up to now specialists of the office carried out the inspection approximately 260 of cylindrical vertical tanks for oil and petroleum product storage. For 146 tanks with volume V= 2000 - 50000 cub.m. capacity their repair was successfully accomplished in accordance with our drafting documentation and author's supervision.

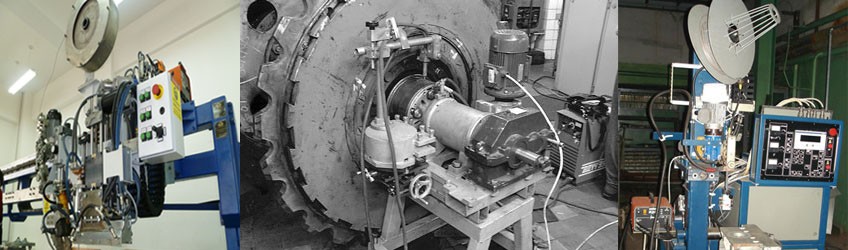

SF “EDTO E.O. Paton EWI NASU” performs the following works to restore steel tanks operability:

- inspection of tanks in accordance with API 653, EEMUA Publication 159 or national standards. Determination of the volumes of repair work and residual life of tank;

- design metal structures for tank’s repair, including seismic loading;

- carrying out verification calculations for tanks;

- inspection and evaluation of the technical condition of the welded joints;

- development of technology for correction the settlement of bottom by lifting tanks;

- development of the technology of welded joints repair following by the results X-ray or ultrasonic testing;

- development the welding technology for tank repair.

|

|

|

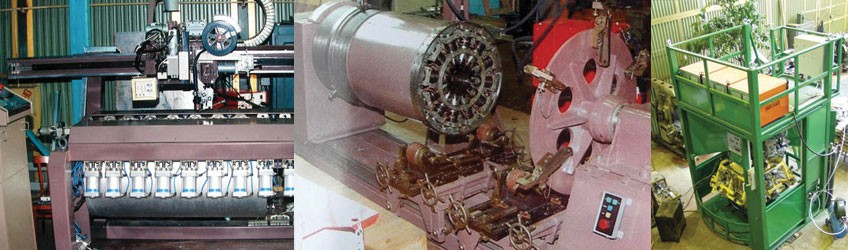

Other direction of office’s activity is developing the metal structure’s projects of various types of above ground tanks for the storage oil and oil products.

Recently we have designed six vertical tanks with volume V = 50.000 cub.m with double-wall, double-bottom and double deck floating roof. During the designing of the shell, with a view to ensure its reliability, the criterion "leak before break" (LBB) was used and developed by us in the context of tanks. This allowed guarantee the safe operation of the double-walled tanks.

Taking into account trend “green technologies” produce electricity we started design biogas reactors, digesters and post-digesters. As a result one biogas reactors with volume V = 8.000 cub.m (D = 22.0 m, H = 21.0m) and one post-digesters with volume V = 4.000 cub.m were designed by our company this year.

Experimental office has successful experience in designing the tanks under seismic action. The tanks with volume V = 5.000, 10.000, 20.000 and 50.000 cub.m were designed for location with the 6-9 points MSK scale.

|

|

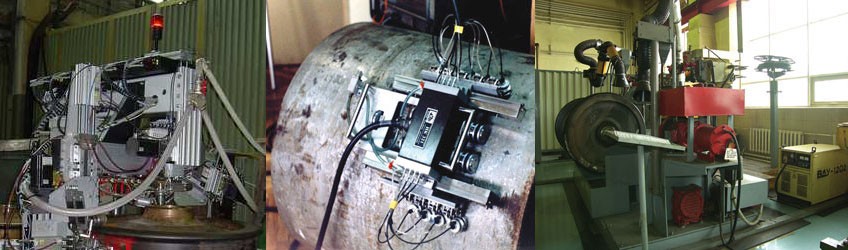

SF “EDTO E.O. Paton EWI NASU” performs the following work on the drafting documentation of above ground tanks:

- design all types of steel tank, including seismic loading, in accordance with API 650, Eurocodes, EN 14015, GOST;

- calculation of the stress-strain state of the shell, roof by finite element method, including seismic loading;

- author's supervision;

- supervising and development the welding technology for erection and fabrication of tank’s steel structures.

We can prepare documentation in both language: English and Russian and operate freely with Russian speaking countries (Kazakhstan, Uzbekistan, etc.). We will be glad to mutually beneficial cooperation in the field of inspection, repair and design of storage tanks for oil and petroleum products, water or other liquids also biogas reactors, digesters and post-digesters.

We are ready to provide your tanks continuous and safely operation life.

Your faithfully,

Chief Project Engineer Andrii Barvinko

Mob: + (38067)-502-7554 (Viber, WhatsApp), e-mail: This e-mail address is being protected from spambots. You need JavaScript enabled to view it.