Machine for welding taps of electric motors armature winding

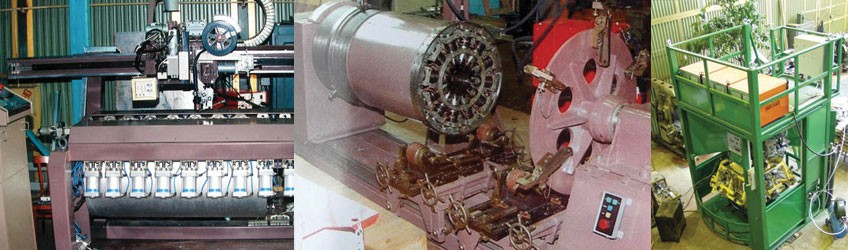

Machine for welding taps of armature windings to commutator bars of drive electric motors instead of brazing – provides a considerable cost effect (in production and repair) due to saving of expensive braze alloys, thus essentially extending the electric motor service life. Welding of taps of armature windings is performed by a nonconsumable electrode in a shielding gas atmosphere, mostly of helium or mixtures on its basis (TIG welding).

Machine for welding taps of armature windings to commutator bars of drive electric motors instead of brazing – provides a considerable cost effect (in production and repair) due to saving of expensive braze alloys, thus essentially extending the electric motor service life. Welding of taps of armature windings is performed by a nonconsumable electrode in a shielding gas atmosphere, mostly of helium or mixtures on its basis (TIG welding).

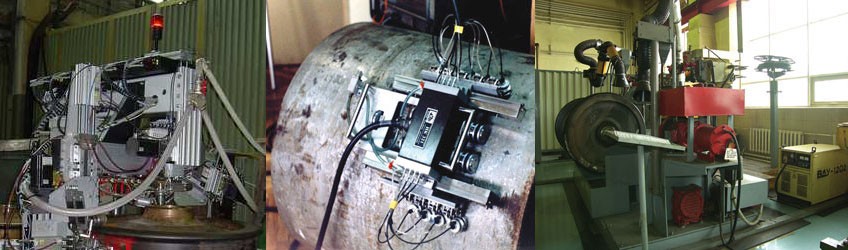

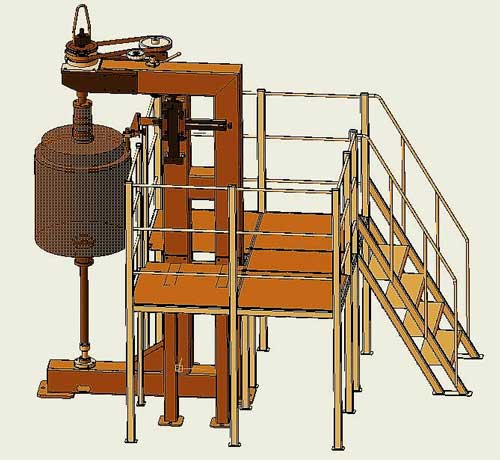

The unit allows performing automatic welding of armature in the vertical position. During welding the armature moves at a set constant speed, and the torch mounted on carriages on a certain row of winding taps, performs welding by a continuously running arc. After completion of welding, the torch returns to the initial position and the armature stops.

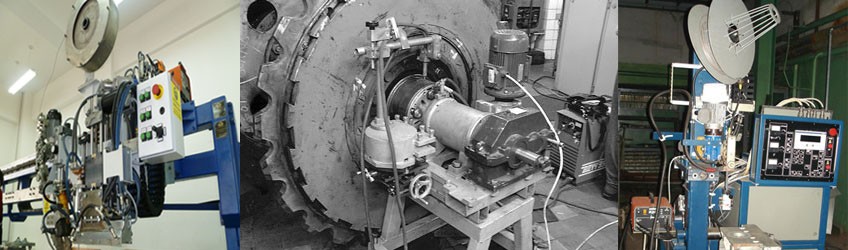

The system set includes:

- - 500 A power source for TIG welding (of VDU 511 type, manufactured by FRONIUS or SELMA) with an oscillator or device for a self-sufficient cooling of the welding torch;

- - rotation mechanism with a controllable rotation drive;

- - device for cleaning the surface of commutator bars during welding;

- - mechanism of welding torch displacement (vertical and horizontal carriages);

- - metal structure (power components) and service platform;

- - set of technological rods for armature fastening;

- - controlpanel (cabinet).