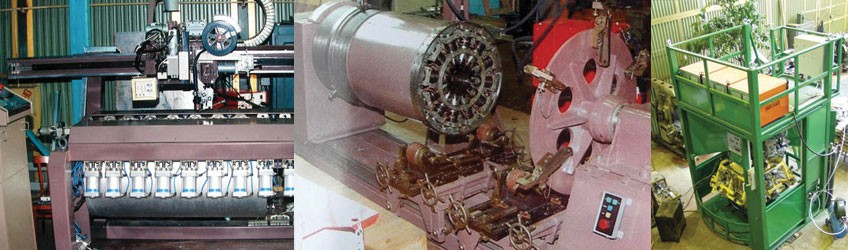

Technologies and equipment for underwater welding. Machine PH-161 "Neptun"

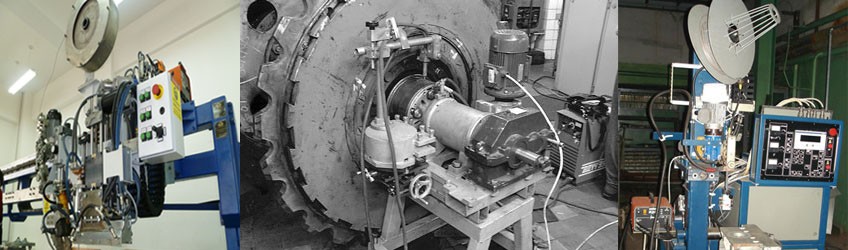

Unique technologies and equipment for underwater welding – allow work performance at any time of the year, in particular under the ice, at increased pressure and at other complicating factors. We guarantee a high quality and reliability of welds and joints of low-carbon and low-alloyed steels. Technologies and mechanization means for underwater welding processes were developed that is particularly important in emergency-rescue operations and operations under hazardous conditions. They allow an essential increase of welding operation efficiency, lowering of welding consumable and power consumption in view of optimization of the entire production process.

Unique technologies and equipment for underwater welding – allow work performance at any time of the year, in particular under the ice, at increased pressure and at other complicating factors. We guarantee a high quality and reliability of welds and joints of low-carbon and low-alloyed steels. Technologies and mechanization means for underwater welding processes were developed that is particularly important in emergency-rescue operations and operations under hazardous conditions. They allow an essential increase of welding operation efficiency, lowering of welding consumable and power consumption in view of optimization of the entire production process.

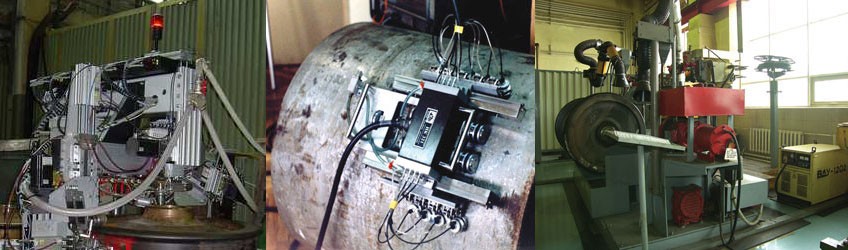

We developed and tried out welding technologies providing new possibilities for performance of particularly critical operations on underwater welding:

- repair of ship hulls directly afloat;

- performance of rescue operations at ships salvaging;

- reconditioning stationary and floating wharfs and platforms;

- repair of port facilities and other metal structures without their dismantling, directly in the water;

- repair of oil, gas and other kinds of pipelines;

- severing sunk and subsurface ships and equipment, when clearing river beds and offshore strips.

We offer the Semi-automatic machine PH-161 “Neptun” - for underwater welding and cutting of metal structures in all positions, both in fresh and sea water at up to 2.0 MPa pressure (at down to 200 m depth), developed by our company. The semi-automatic machine consists of two connected modules: immersible (underwater module with feed mechanism and electrode wire) and above-water (control cabinet). Welding current 500 A, welding wire ø1,6-2,3 mm, speed of submission welding wire 100-600 km/h, weight of the cartridge with a welding wire (capacity) 10,0 kg.

Our firm disine also technologies of hardfacing the wear surfaces by flux-cored strip and wire.