Technologies of hardfacing the wear surfaces by flux-cored strip and wire

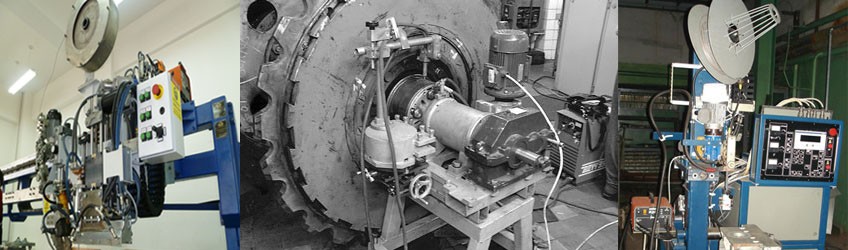

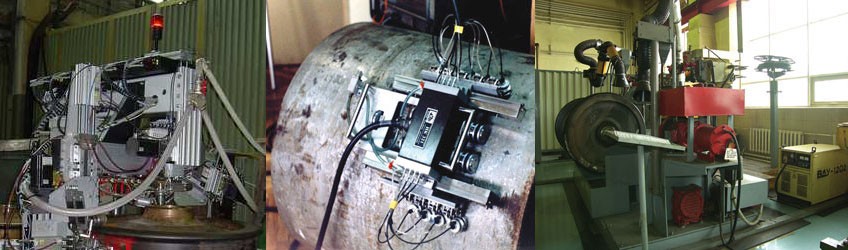

Technologies of improvement of the reliability and fatigue life of equipment by the method of hardfacing the wear surfaces by flux-cored strip and wire alloys are designed for protection of metal structure surfaces under the conditions of abrasive wear in reactive media, exposure to increased temperature, contact-shock loading, hydroabrasive, cavitation and gas-abrasive wear. Flux-cored welding consumables guarantee an unprecedented corrosion resistance of the treated surface, considerable increase of their wear resistance, extension of facilities service life, considerable saving of labour resources and circulating assets in repair-reconditioning operations and service, as well as high labour efficiency at welding process automation.

Applications of flux-cored hardfacing consumables:

- repair and performance of hardfacing on any metals – conventional, alloyed and stainless steel, non-ferrous metals and cast iron;

- equipment and trunks pipelines armature in oil-gas and power generation industries;

- parts of metallurgical equipment, agricultural machinery, road and construction machinery, motor transport, wood-working, drilling equipment, etc.

Оur company specialists can perform the following operations in the shortest term:

- - manufacturing of flux-cored strips and wires for arc welding and hardfacing for the specified purposes;

- - development of new grades of flux-cored strips and wires with specified parameters;

- - assistance in putting into production flux-cored welding consumables and technologies.

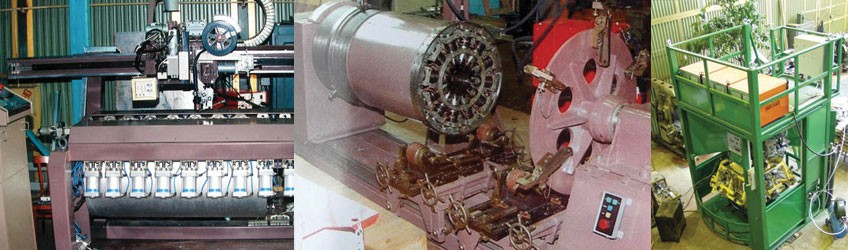

For realization of hardfacing works automatic machine of type UD-681, UD-683 for mechanized hardfacing cases of armature, cases of latches, the equipment on plasma hardfacing rods of armature can be put, etc. Our enterprise makes flux-cored strips and wires and a tape for pipeline armature of marks PP-АN133, PL- АN157, PL-АN150 etc.