AUTOMATIC MACHINE FOR WET UNDERWATER WELDING IN CONFINED SPACES

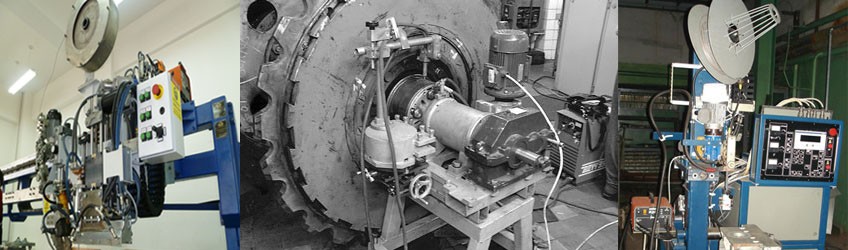

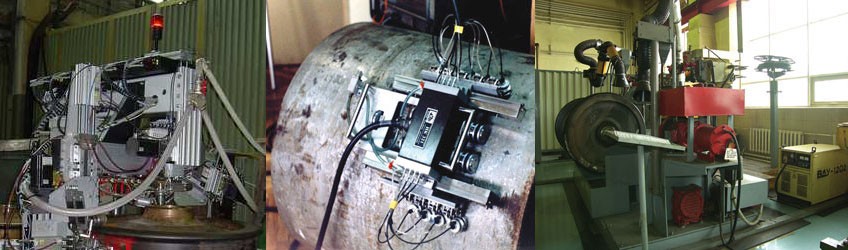

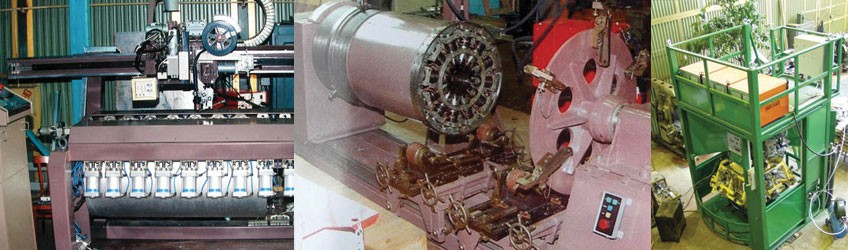

PWI developed technology and equipment allowing performance of automatic flux-cored wire wet underwater welding of structural elements, reliably insulating the lower part of heat exchanger column. The unique aspect of the work consists in development of an automatic welding machine, capable of operating when immersed into a pipe of 119 mm inner diameter into liquid heat carrier medium at 200 m depth. The semiautomatic machine was designed with application of special torque electric drives for electrode wire feed and welding displacement mechanisms. A special cable with welding and control wires was developed, capable of operating at a large distance from the arc power sources and control system. Cable uncoiler design was also developed, with digital recording of automatic machine position along the pipe length. Approbation results showed that application of special automatic machine allows increasing heat exchanger reliability, reducing time loss during performance of work on its sealing, rational use of site area and reducing financial expenses. 5 Ref., 8 Figures.