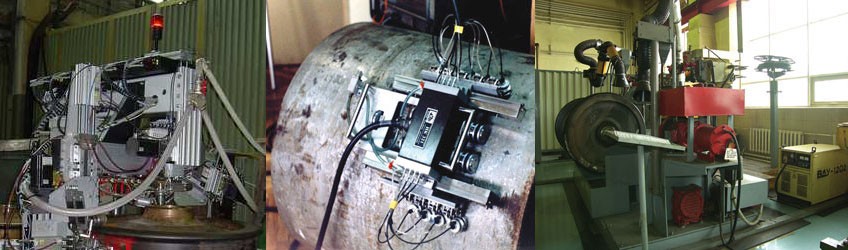

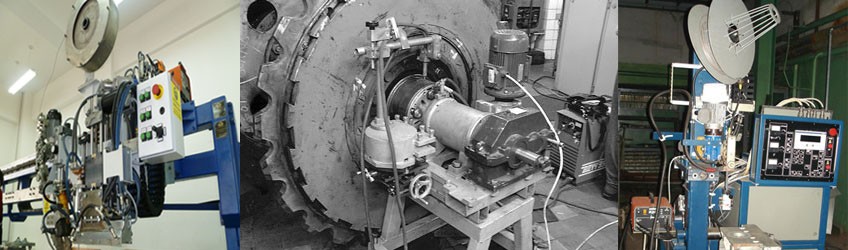

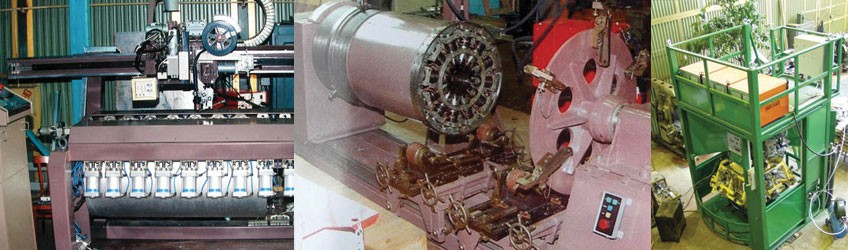

Technology for mechanized pulsed-arc consumable electrode welding with the pulsed mechanism for automatic feeding of welding wire. Machine PSh-007

For the first time in the world practice – the technology for mechanized and automated pulsed-arc consumable electrode welding, which features application of the pulsed mechanism for automatic feeding of welding wire synchronized with the operation of the pulsed source of welding current. Both the sources (pulsed current and pulsed feed of wire) are interconnected by automatic means – by an optimum algorithm of control of electrode metal drop transfer that allows an effective redistribution of melting energy of the electrode and base metal. Presented technology allows achieving in practice a considerable reduction of energy, labour and other resource consumption.

The main advantages of the new technology of pulsed feed of welding wire are:

-considerable lowering of power costs for forming the current pulses (by 1.8 times);

-reduction of spattering losses of welded structure base metal;

- reduction of electrode metal losses (1.5 – 2 times);

- possibility of controlling the weld dimensions (up to 3 times);

- improvement of structure of weld and deposited bead metal;

- elimination of welding drop overheating;

- possibility of welding process application in a broad range of modes and

- for the first time in pulsed-arc welding –

also with flux-cored wires;

- ability to operate in the mode of pre-set current source power;

- ability to perform work

- for the first time in pulsed-arc welding –

in any direction;

- improvement of labour conditions and lowering of qualification requirements to personnel.

Our creative collective develops new Automatic welding machine РSh-007. It represents the source of a welding current, connected and synchronized with the pulse feeder of a welding wire. Pulse submission of the welding wire creates optimum conditions of carry of the welding drop in the welding bath. Welding current 40-315 A, electrode ø0,6-2 mm.