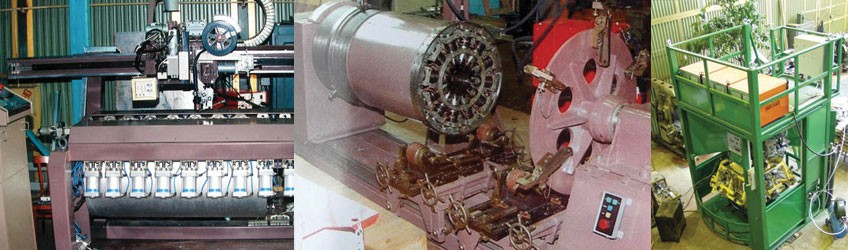

Fig. 1

The new power saving technology for improvoment of the efficiency of heat-exchange surfes of flat oval pipes

Innovation project developed together with NTUU “Kiev Polytechnic Institute” for the first time in the world practice – power-saving technology for improvement of the efficiency of heat-exchange surface of flat oval pipes with welded-on stiffeners (resistance welding). Flat oval pipes with incomplete finning of the surface (Fig.1) are applied in different industries (petroleum processing, chemical, gas, food industries, in gas transportation system, etc.) as heat-exchange carrier: water economizers, boiler unit heaters, boilers-utilizers, regenerators, oil coolers, dry cooling towers and air capacitors. Mastering new heat-exchange surfaces will lead to a considerable saving of metal (by approximately 1.5 – 2 times) and power resources, as well as lowering of the price for one running meter of pipes.

Flat oval pipes with incomplete finning have a number of important advantages:

- - adaptability to fabrication and relatively low production cost;

- - highly developed surface (up to 1.8 m2 per a running meter);

- - high intensity of convective heat exchange;

- - have practically ideal thermal contact between the fins and load-carrying pipe;

- - have low aerodynamic resistance;

- - have lower thermal resistance of heat dissipation compared to round pipes.

Based on certification results, during the operation period starting from December 2009 till January 2010, the economizer has operated for 1056 h, here boiler efficiency increased by 5%, and 114 thous. m3 of natural gas were saved.

By our estimates the payback period for such a utilizer does not exceed one heating season.

The semiautomatic machine on welding edges on flat oval pipes is developed.