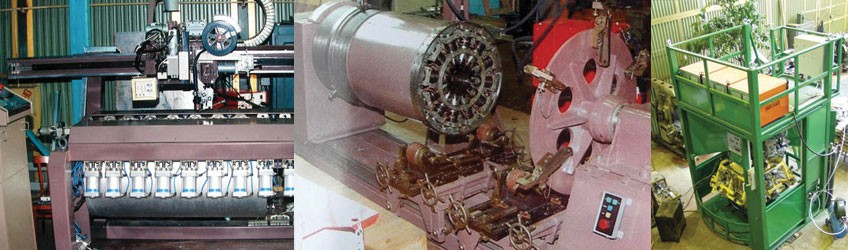

The specialized assembly machine of new generation AD-381

Fig. 1

The specialized assembly machine of new generation AD-381 (Fig.1) is intended for single-pass electroslag welding metal by thickness of 30-100 mm. The machine is supplied with two submitting mechanisms for wire ø2-4 mm with separate, independent regulation of speed of submission of each of them. Welding current 1000 A. The machine will consist of four modules quickly mounted with the help of a key without additional tools, that considerably reduces time at performance of the electroslag welding seam. As a directing rail used rolling steel angle by section 50x50 mm. The running carriage of maghine, moving on directing rail, besides performance of welding can serve as the running mechanism as for the cutting torch by preparation of joints under welding, and also for the machine providing the subsequent processing of welded connection.

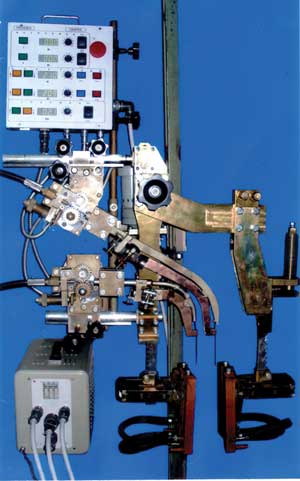

Fig. 2

The machine is successfully tested under production conditions the metallurgical enterprises at repair and a construction of cases of blast furnaces and cases of converters. Welding of metal by thickness of 40-45 mm is made with a speed about 4,0 km/h, metal thickness of 80-100 mm – 1,5 km/h. The block of automatic control is equipped with digital indicators of speed of welding, speed of submission of each electrode and voltage of welding on each electrode. Use of machine AD-381 allows to raise considerably productivity of work at mounting large-sized etal construction and to receive welded connections stably repeated high quality. For example, еlectroslag welding by one machine accelerates process of performance of seams on ring of the blast furnace in 2 times, and labour input thus decreases in 8 times (Fig.2).