Complex of means machanization welding processes

Application of means mechanization welding processes allows to raise productivity and quality of welding in all spatial positions, with application of various ways of protection. Offered welding machine allow to facilitate essentially work of the welder, is easily built in industrial technological lines. Welding current - no more than 360 A, electrode ø2-3 mm.

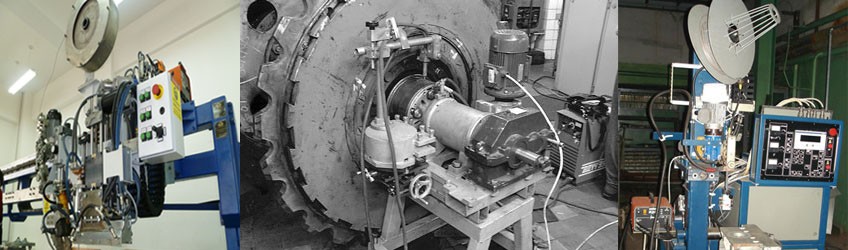

Welding automatic machineA-1698 (Fig.1) is intended for automatic electroarc welding angular seams by cathetus 4-8 mm in the bottom position in the environment of carbonic gas, with flux, with a speed 15-40 km/h and speed of submission wire 260-630 km/h. The automatic machine also is used for semi-automatic welding in the environment of carbonic gas.

Welding automatic machineA-106 (Fig.2)is intended for welding in carbonic gas by tandem in the bottom position of angular seams in cells bottom of section case construction of courts, with speed 30 km/h. The automatic machine provides:

- smoothly adjustable submission of electrode wire;

- moving along the seam smoothly, with in steps adjustable speed;

- control of gas submission;

- automatic denergizing at arrival on the emphasis.

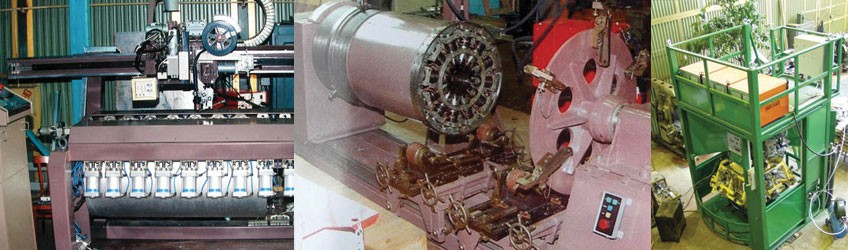

Welding automatic machineA-1711(Fig.3) is intended for automatic electroarc welding in the bottom position in the environment of carbonic gas simultaneously two angular seams with a speed of 10-30 km/h. The machine moves on a vertical shelf of products tauri sections, provides submission electrode wire in a zone of an arch. The machine eats voltage of a welding arch.

The machineA-1689P (Fig.4) is intended for automatic electroarc welding in the bottom and vertical positions in the environment of carbonic gas angular and butting seams with speed 5-35 km/h. The machine is the portable adaptation for moving welding torch of the semiautomatic device and allows to mechanize gas electric semi-automatic welding.