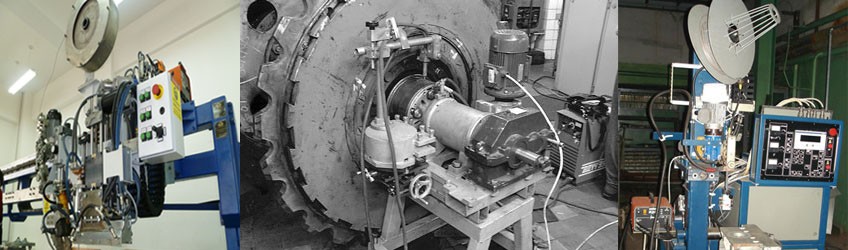

New generation of small-sized Machines series AD-333. The carriage AD-334

New generation of small-sized Machines series AD-333 (Fig.1) of various updatings are intended for arc welding with compulsory formation of a seam vertical, inclined, curvilinear, not rotary ring, and also horizontal joints (on vertical planes) of metal thickness of 8-60 mm at manufacturing, repair and installation sheet metal construction (Fig.2). Welding current - no more than 500 A, voltage of an arch 24-40V,electrode ø2-3 mm. The technology of welding is characterized by full absence of angular deformations and small cross-section contraction (up to 2 mm). The technology allows for one pass at one or to bilaterial welding to receive еqually strong with the basic metal welded connections. All machine of a series are supplied with devices for automatic maintenance of a level of a welding bath concerning the top edge of the forming device.

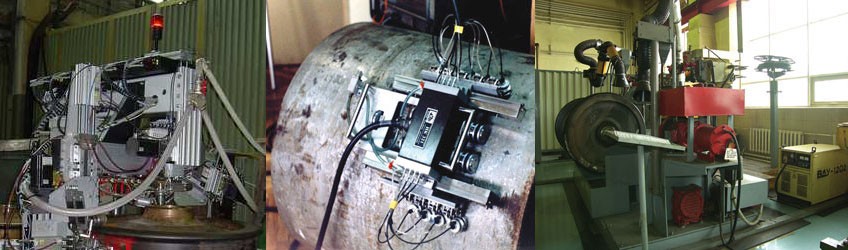

Fig. 2.

The carriage AD-334 (Fig.2) is intended for the mechanized moving to all spatial positions of a gas or plasma cutting torch, the holder a semiautomatic device for welding joints or hardfacing with adjustable fluctuation of the electrode perpendicularly to cutting. The device also can be used for moving the control sensor above a joint at the control of process welding. Joints can be direct, ring or curvilinear, with radius of curvature not less than 150 mm. The device is executed as the easy buggy in weight of 6,5 kg, which moves on without free motion on directing rail from rolling not processable angular steel 50х50 mm (for direct joints) or from a flexible strip 68х4 mm (for curvilinear joints). Speed of moving the carriage is smoothly adjusted within the limits of 0-72 km/h. Rails can be fixed on constant magnets at installation or on racks – in stationary conditions.