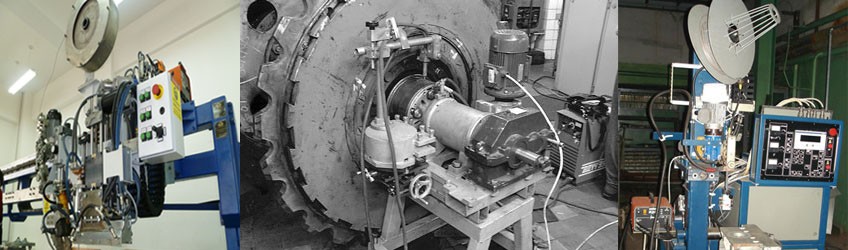

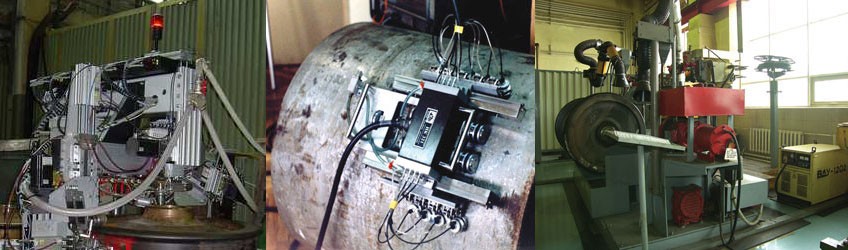

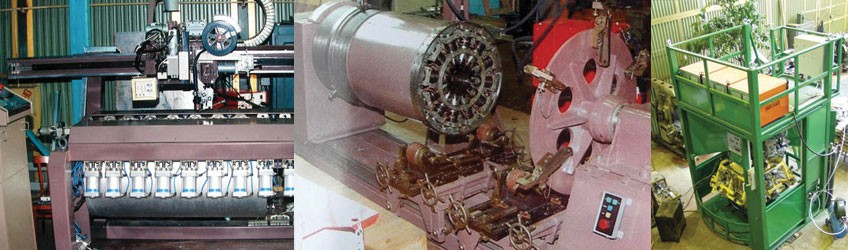

New generation automatic machine UD-682 is designed for welding plate bodies

New generation automatic machine UD-682 is designed for welding plate bodies by narrow-gap TIG with magnetic control of the arc (UD 682) and allows complete automation of electric arc welding process by a unique technology – by the method of automatic following of welding electrode position using a special device – arc sensor. Welding is performed by argon-arc process with tungsten electrode and filler wire, in several passes (number of which depends on welded item thickness). Components of leading foreign and local manufacturers are used in the machine. Automatic welding machine is applied in manufacture and repair of large-sized metal structures 20 – 110 mm thick.

Applied technology provides high quality parameters of welds, an essential improvement of efficiency of welding operations performance (up to 10 m/h speed), lowering of non-productive material losses (welding wire and base metal spattering), as well as power losses – due to optimization of welding processes in all the stages. Automatic system of following the electrode position in the weld center provides control of the mechanism of horizontal displacement of the welding head, and automatically maintains the specified arc voltage. Following of electrode position in the weld center is implemented using a device specially developed by us – an arc sensor. The arc proper acts as a sensor during the following process. Based on arc voltage measurement by a special control module a signal is applied to the controller, which controls the horizontal drive of the welding head during welding. Control system also provides an automatic maintenance of the distance from item surface to protective “cap”.